Smart. Simple. Sustainable.

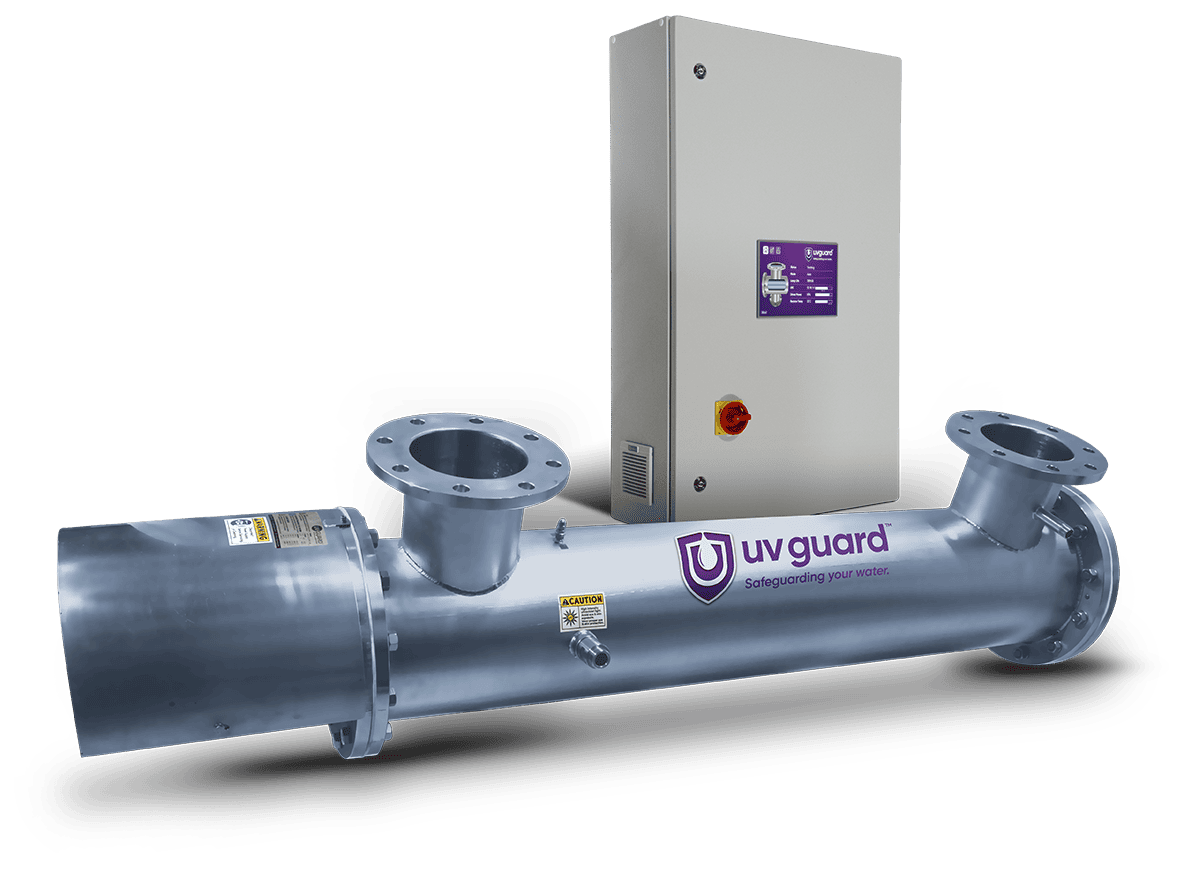

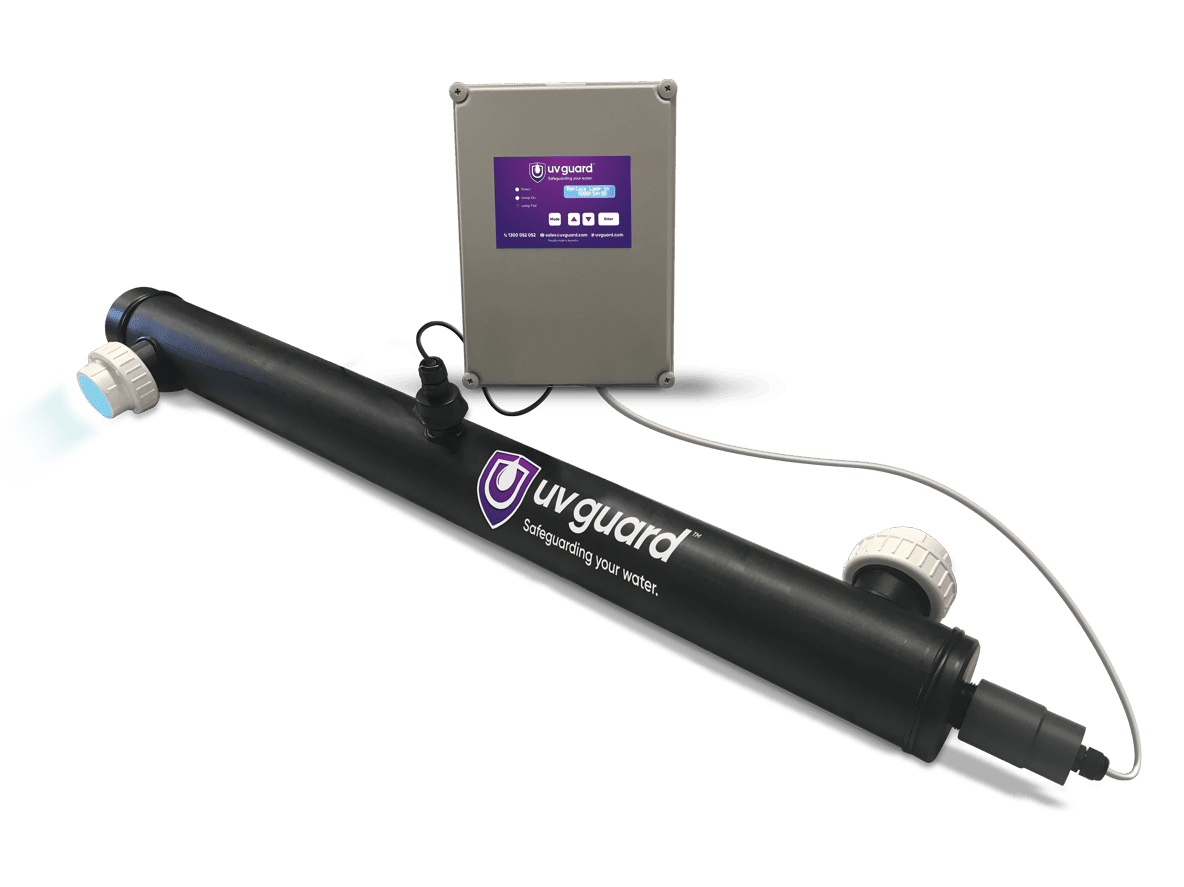

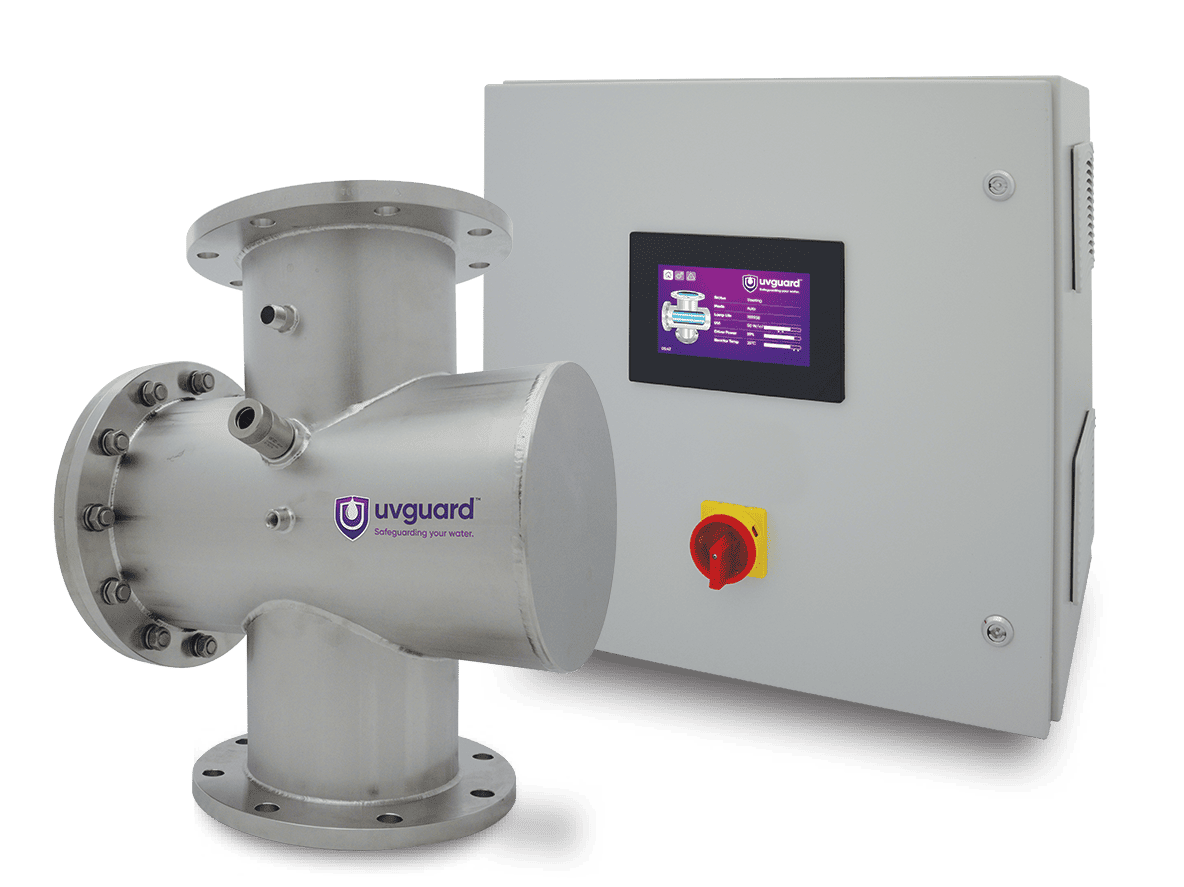

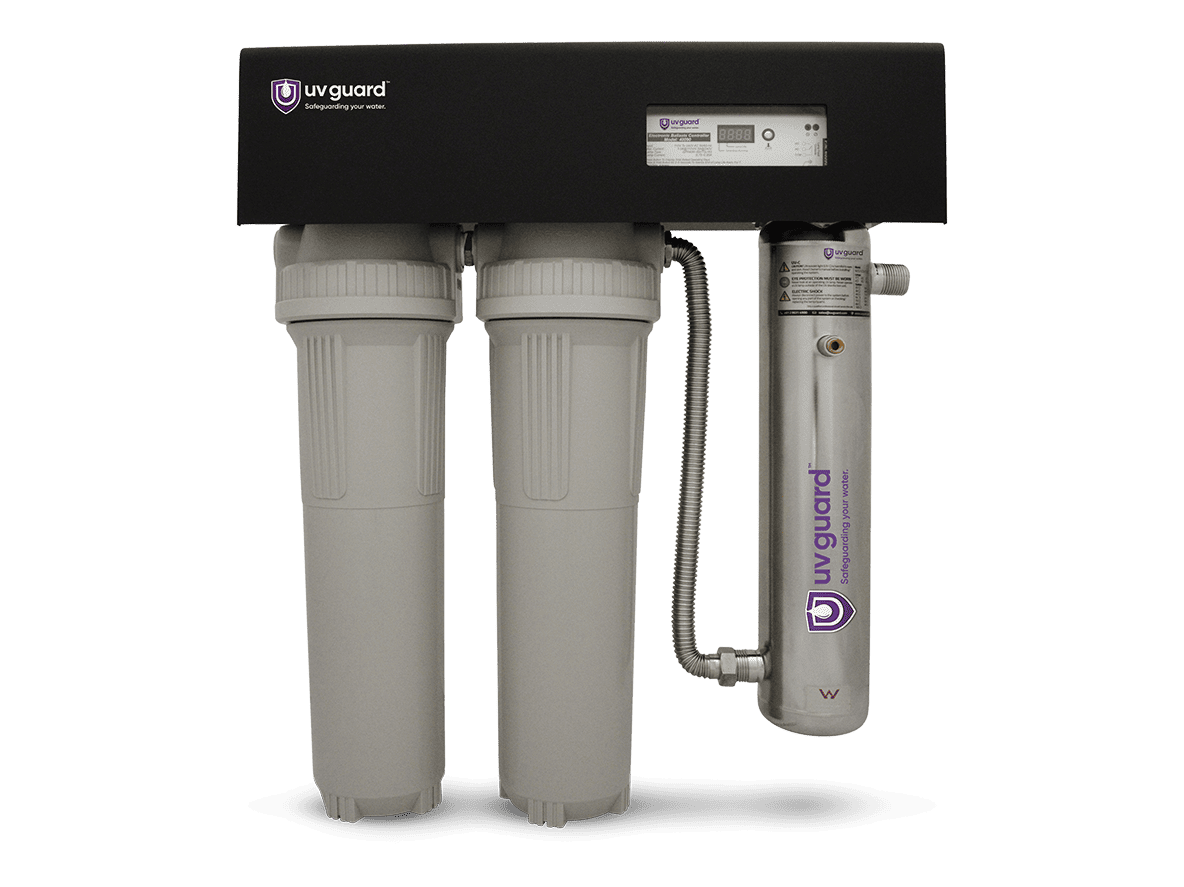

UV Guard delivers innovative, chemical-free purification technologies that use the natural power of UV light to treat water and other liquids – simply and sustainably. Every day our market-leading disinfection systems are trusted by industrial, commercial and domestic users across Australia and around the world.

Testimonials

Get in touch

This website has lots about us. But it’s your needs that matter most. Let’s talk.

Newsletter

Stay up-to-date with our very latest news, technology, offers and events.