Customer

Coca Cola, Richlands, QLD

Application:

UV disinfection for sugar syrup

Project Background

Coca Cola is a major manufacturer of beverages including soft drinks, bottled water, sports drinks and fruit juices. Coca Cola in Richlands Queensland was installing a new production line which required Ultraviolet (UV) disinfection for the sugar syrup application. The UV system on the existing production line also required an upgrade.

Concentrated sugar syrups have a high osmotic pressure. This high pressure prevents micro-organisms from growing; however yeast and mould spores can survive and grow once the syrup is diluted. Microbial growth can cause discolouration, spoil the syrup and it increases risk of infection or illness upon consumption.

In this instance, pasteurisation of the product was not an option. The required duration of high temperature to ensure the required reduction was achieved would ruin the colour and flavour of the product.

The sugar syrup food and beverage requires a particular UV dose to deactivate the DNA of the spores. The sugar syrup manufacturing process has very stringent regulations around monitoring and safety; therefore the system must be effectively monitored to ensure a continuous treatment process.

Coca Cola specified that a 5 log reduction of bacillus bacteria was required.

UV Requirements

UVT of 35%

Peak flow rate of 20 m3/hr

Required UV dose of 150mJ/cm2 – for a 5 log reduction of bacillus bacteria

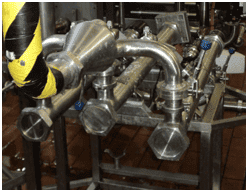

UV Guard’s Solution

3 x UVG MP SS-3.5 in parallel

1 x UVG MP-7.0

Like all sugar syrup UV disinfection systems, high intensity UV lamps combined with thin film food grade compliant chambers are required due to the low UV Transmittance associated with sugar syrups. As specified by Coca Cola, the systems needed to be able to generate a UV dose large enough to reduce bacillus bacteria by 5 logs (99.999%).

If you have a food and beverage water treatment enquiry, contact a UV Guard process engineer today.

Stopping the spread of viruses in aquaculture research facility

The aquaculture facility had multiple research stations all independently researching different fish species at the same time, and each one of these stations required its own UV system to treat the water entering that specific area. Additionally, all seawater entering the research facility needed to be treated. All UV systems needed to be selected to achieve minimum UV doses to achieve sufficient inactivation of viruses such as white spot.

Proof low pressure UV treatment is an effective approach for public swimming pools

A 25m public swimming pool was struggling to implement consistent reductions in chloramine (combined chlorine) levels – especially during peak swimming periods. In addition, enrolments at their learn to swim classes had failed to increase for the past 2 years due to parental concerns about allergic reactions to chloramines such as trichloramines.

Underwater World – UV disinfection for sea water aquarium

Underwater World in central Mooloolaba, located in the heart of Queensland’s famous Sunshine Coast is renowned for being the area’s top family attraction. The aquarium is home to a range of marine life including fish, sea animals and corals. The marine life must be protected from a range of diseases including bacteria, fungi, viruses and protozoa.

Get in touch

This website has lots about us. But it’s your needs that matter most. Let’s talk.

Newsletter

Stay up-to-date with our very latest news, technology, offers and events.