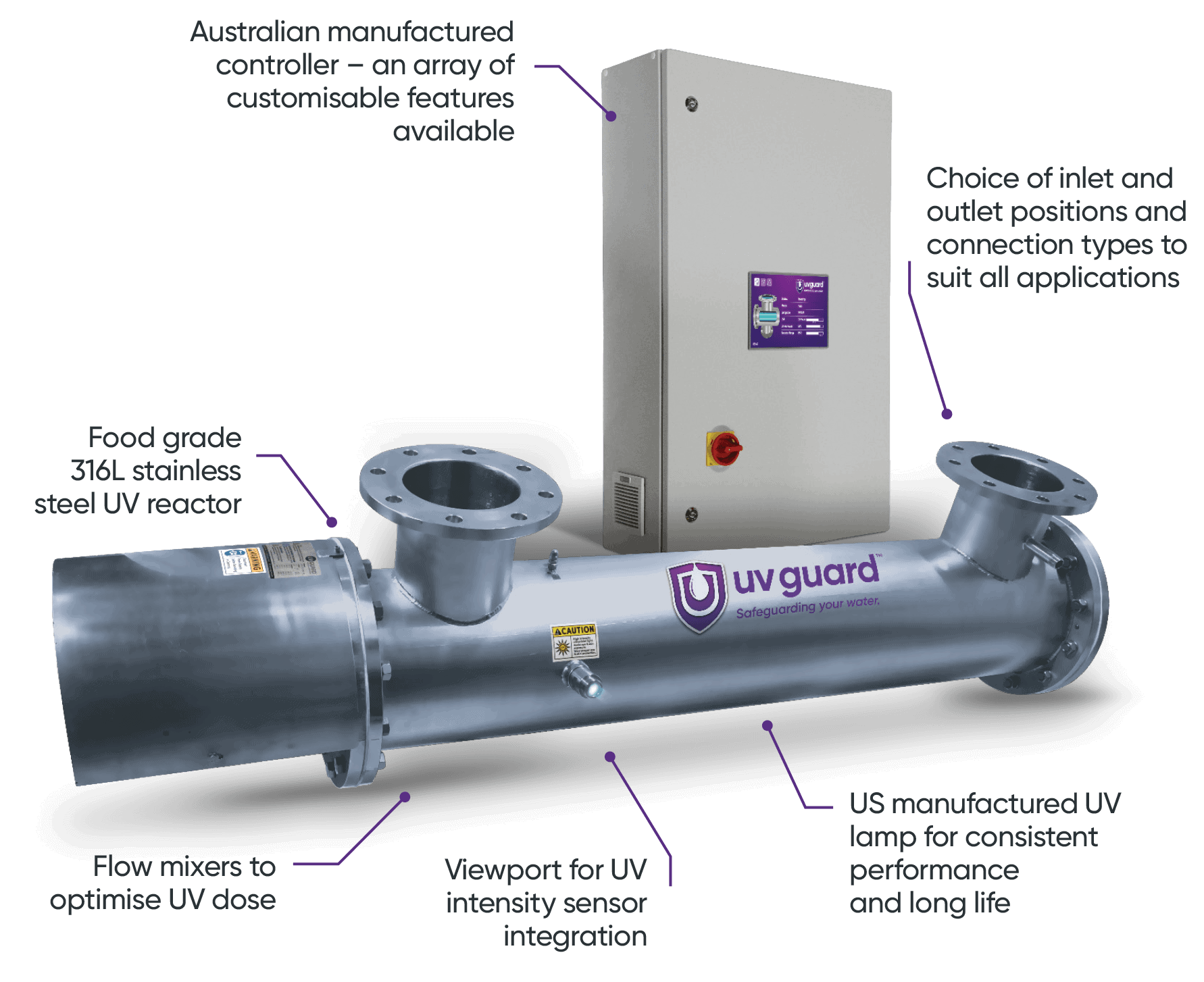

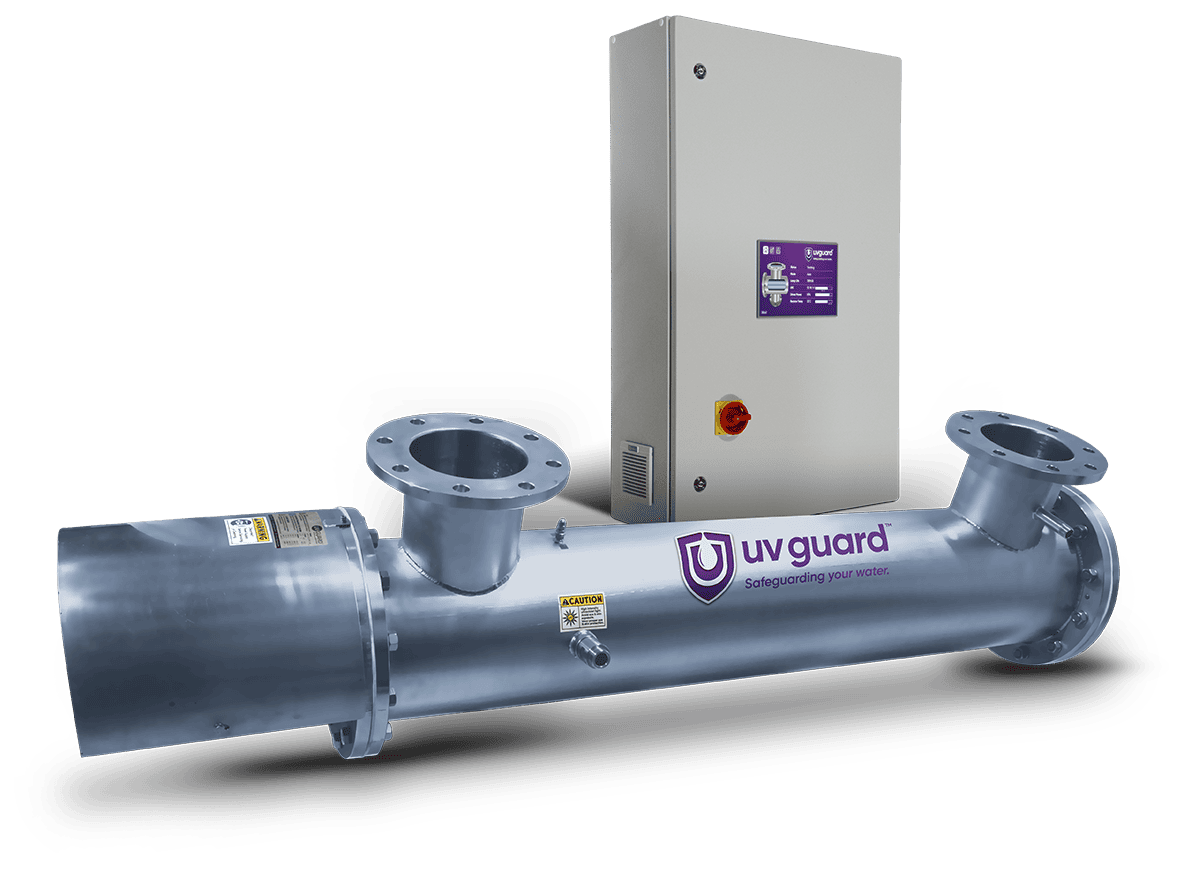

X-Series™

Compact UV disinfection for large-flow Commercial and Industrial applications.

Product Information

UV Guard’s X-Series offers a range of highly customisable WaterMark-certified UV disinfection systems. Designed for long life with low maintenance, units are ideal for liquids with low UV Transmittance (UVT), high UV dose requirements and large flows (700m3/hour and beyond). Suitable for an extensive range of commercial and industrial applications.

Testimonials

Get in touch

This website has lots about us. But it’s your needs that matter most. Let’s talk.

Newsletter

Stay up-to-date with our very latest news, technology, offers and events.